Industrial Internet of Things (IIoT - Industrial Internet of Things)

The first example of such technology is the Internet of Things (IoT), which connects individual Things (appliances, “smart” technologies, security systems, etc.) via the Internet (network). The Industrial Internet of Things (IIoT) operates on the same principle. Using the Internet (industrial network based on industrial communication protocols), it connects Things (i.e., production lines and their stations, factories, power plants, robots, systems and their subsystems, etc.). Various companies offer different solutions, starting with the technology itself, hardware/software solutions for individual components of this technology. Today, companies offer comprehensive IIoT as a service, even in the so-called cloud.

IIoT services, just like its classic IT counterparts, focus on both functionality and security, ensuring the safety and protection of the entire connected system. All functional and quality requirements (so-called non-functional, e.g., quality goals, availability, reliability, maintainability, security, protection) need to be implemented separately into individual objects (Things) so that they are capable of performing their function independently. At the same time, the principle is to connect elements to ensure that a more complex interconnected system brings new and superior functions or increases overall efficiency. This means that all elements in the system must be identified and capable of mutual communication. Security methods and the safety of such complex systems represent a separate and very extensive field.

Digital twin

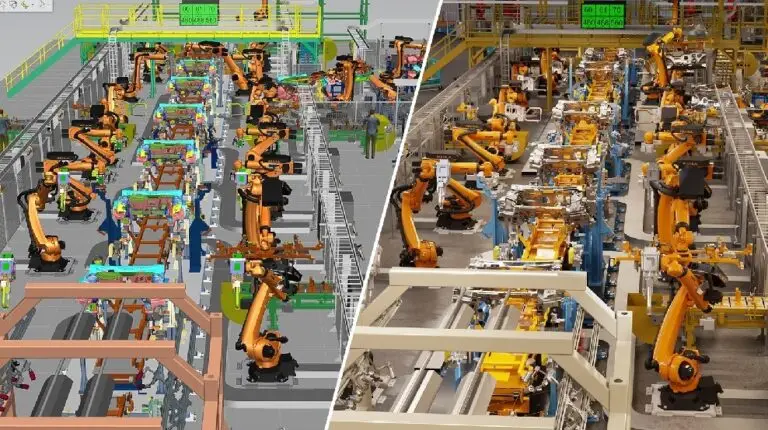

A Digital Twin is a digital representation of various Things, i.e., objects, products, systems, and technologies, which may be part of an IIoT system. It is essentially a digital image of a real physical element. This can be thought of as a model in the product design phase, which can be gradually expanded throughout the product lifecycle or any system’s lifecycle. Models and modeling approaches are also a separate field in various disciplines. However, a Digital Twin is not just about the model of the object; it also involves connecting them and exploring their relationships, synergies, and conflicts.

The real object is connected to its virtual counterpart, and individual physical parameters are updated in its digital twin over time. In the digital realm, the system can be experimented with, verified, simulations can be conducted, and artificial intelligence can be applied to investigate various phenomena, functionalities, and qualitative properties. This technology is highly applicable throughout the entire lifecycle of complex systems, from their design and verification of higher-level functions to operation, changes, and eventual shutdown or replacement by another system.

Technologies implement, similarly to the previous case, identification techniques for objects in the real system, extended to their digital counterparts in a parallel environment.

Virtual 3D space or Industrial Metaverse

The term “Metaverse” can be understood as a virtual 3D world or virtual reality. We can connect to the digital world using a traditional PC or even a smart mobile phone. For a real 3D effect and the perfect sense of a virtual 3D environment, we currently have 3D glasses available, or other devices that can create similar 3D glasses, even from a regular smartphone. Google Play has been offering apps supporting virtual reality (VR) for years, using the mentioned glasses and VR features of mobile phones. Anyone can try out a virtual 3D space for free on platforms such as Decentraland or VRChat, among others.

Industry has not fallen behind and is trying to apply the acquired knowledge in its own applications. The goal is to build a virtual environment with the implementation of already created digital objects. The vision for industrial virtual 3D spaces is vast. Imagine a project for a large technological complex, a chemical plant, a power plant, a production line, or other large complex products. When solving technical problems, as well as during business and managerial meetings, everyone has access to a virtual world where the physical solution is seen in its virtual copy. It is a representation of digital twins in a 3D virtual space, i.e., models on which we can apply planned changes, conduct experiments, and apply artificial intelligence to find desired outcomes. It is also essential to search for faulty functions and features of complex systems. More on this will be discussed in upcoming articles.

And what is and will be the practice?

As already mentioned, the technologies discussed have high objectives. However, as with everything, it depends on the approach and human creativity. Overly optimistic expectations can lead to impractical, costly, and inefficient solutions. In the worst case, if the principles of modeling are misunderstood, it may result in neglecting fundamental physical properties of the real world. This also leads to unsecured states of technology and connections between systems. Due to the complexity and heuristic nature of artificial systems, security disciplines will need to focus on higher goals and principles of safety, tailored to this field. On the other hand, the same technologies and principles can be used to benefit safety.

In any case, new technologies push the industry forward, and even with many blind and costly paths, there will still be smart and effective solutions. If the industrial virtual space provides suitable solutions for multiple industries within the system lifecycle, it can become an effective and highly useful tool that leads to the development and modernization of the industry.

The current trend shows that large companies are investing huge resources into these technologies. In the IT world, traditional companies such as Google, Nvidia, Meta (formerly Facebook), Unity, and Qualcomm are leaders (see for example These 8 Tech Giants Have Invested Big in The Metaverse (makeuseof.com)).

In the industrial world, for example, Siemens Corporation announced a partnership with Nvidia and launched the Xcelerator program to support the industry in this direction.

We will continue to monitor technological trends in our section and keep you informed. There is much space to explain the individual technologies, their qualitative properties, and especially their safety and security. Exactly as we have set out in our vision and mission.